No, you can’t buy it ready made, but with the exception of the power supply and nichrome wire, all the parts come “off the shelf'” from your local Home Depot home center or equivalent (HQ, Lowes…). Since there are many different possible variations on the details, I’ll just provide the philosophy and let you adapt whatever materials you can find. Study the photos below and you should have no problem producing your own hot-wire “bandsaw'” with minimal effort. Not only will this cut beaded or blue styrofoam board, but it also cuts nylon sail cloth (providing a melted, ravel resistant edge) and thin polystyrene sheet (e.g. “Plastruct'”).

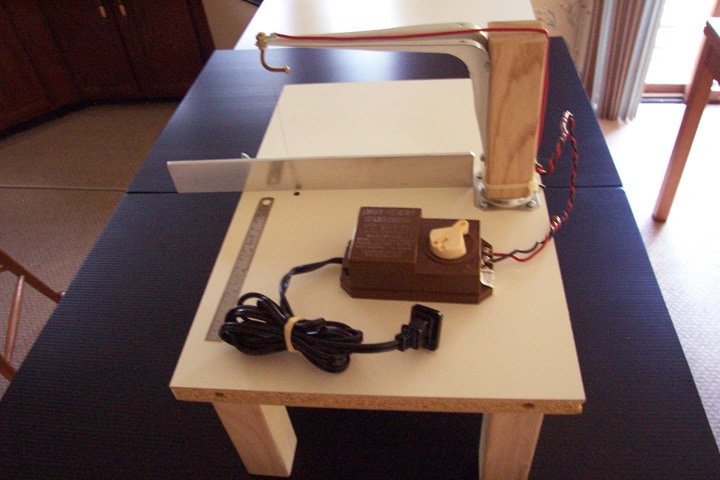

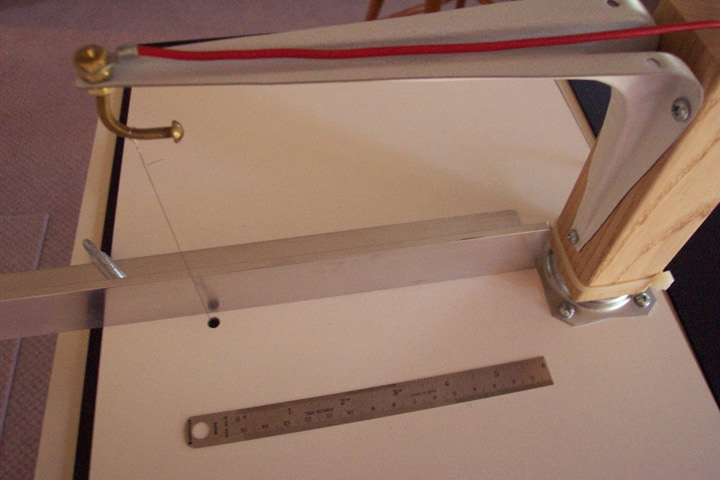

The basic unit consists of a prefabricated white vinyl clad shelf board from a modular shelving system. Mine measures 17 3/4” X 11 3/4” X 3/4” and provides a smooth, clean table. It is supported on pre-made furniture legs and mounting brackets sold for do-it-yourself table construction. The legs are rectangular measuring 1 1/2” X 1 1/2” X 6”. The steel mounting brackets are attached to the shelf board with #10 self tapping screws. Pre drill the holes for these carefully, and pay close attention to the length of the screws, so they don’t poke through the tabletop. The shelf material is particle board, and without pre-drilling it will crumble or crack badly, so be warned. The bracket assembly which supports the wire is made from another table leg, mounted to the top rear of the table with another steel bracket, and a standard 7 1/2” X 5”shelf reinforcing angle bracket, typically used in closets. This forms the support arm to which the wire is attached. The wire passes through a 1/4” diameter hole in the table and is looped around a spring which in turn is looped over a screw supported by a 2 1/2” steel corner bracket bolted to the table bottom. The top support is a bolt bent to a “question mark'” shape, and again, the wire ends in a loop, which rests in the screw’s threads. I bushed the hole in the table with 1/4” OD aluminum tubing, to prevent burning the tabletop if touched by the hot wire. The spring is necessary to maintain tension as the wire is heated. It will slacken significantly at high temperature without it. My Home Depot has a large selection of springs available, and I chose one about the size and stiffness of a ball point pen spring. Obviously the tension should be substantially less than the breaking strength of the wire but is otherwise not critical.

The only critical part of the project is to ensure that the wire ends up strung perpendicular to the table, and passes approximately through the center of the hole in the table. In practice, perfect alignment is very difficult to achieve, so some small degree of adjustability needs to be built in. The approach I took was to use the threads of the screws to which the spring and wire attach at either end as “micro adjusters”. That’s why the top wire mount is oriented 90 degrees relative to the bottom one, so that the wire can be adjusted in each direction to provide final alignment. The only difficult operation was bending the top wire mount from a #10 brass screw. I did this with a torch, and handled the screw with pliers which grabbed some nuts threaded onto the screw, to prevent damage to the threads. This was a real pain, and took several failed attempts. A better approach would be either to bend the shelf bracket end by 90 degrees and simply thread an unbent screw to it, or else attach another small 90 degree bracket to the end and bolt to that. Bending a screw 90 degrees is really a pain! I can adjust each end of the wire by moving the loop in the wire or spring from thread to thread until alignment is perfect (use a square). I can also rotate the arm in its mount slightly, providing a further tweak, which is useful for getting the arm right over the hole in the table.

For the wiring, I used spade lugs to attach the power supply wires. The lugs are trapped between nuts threaded onto the wire-mount screws at each end. I routed the wires with cable ties to keep them neat and out of the way. Yes, all of these goodies are available at the Home Depot! To mount the nichrome wire, pass one end through the free loop of the spring, and twist it around itself to form a loop. Pass the free end through the hole in the table and pass it over the top mounting screw at the end of the arm. Pull some tension in the spring to keep the wire taught, and wrap it around itself to form the top loop. Trim the excess, align it with a square, and you’re ready to cut!

As for the electrical end, I’m using 0.008” diameter nichrome resistance wire, with a nominal resistance of 12 ohms/foot. Sig manufacturing sells nichrome wire for cutting foam wing cores. My set up ended up having a cold resistance of approximately six ohms, which therefore draws approximately one ampere at six volts. Things vary a bit since the resistance of the wire varies with temperature, and hence, current. Initially I used a cheap electric train transformer for a power supply, which provides excellent adjustment of the wire temperature due to its finely adjustable output voltage. This works well with only one wrinkle: it has a thermal circuit breaker built in which causes it to shut off after 15 minutes or so of continuous use. I’m now using a power supply from Jim Fackert, which can provide up to two amps regulated output for voltages between six and twelve volts. The drawback is that the output voltage can only be selected in 1 1/2 volt steps. Ultimately, I may combine this with a potentiometer to get finer control, but the 6 and 7.5 volt settings both cut well. I suspect that a heavy duty electric train transformer would work fine, it just has to supply one to two amperes without overheating. Bear in mind that alternating current is fine in this application, so a variable output AC transformer which can handle two amperes between six and twelve volts will also work. Maybe there is a power supply that will work sold for some other purpose at the Home Depot…