When I first decided to create my own home haunt I realized that it would be nice to have something to set the front entrance apart from the standard doorway or simple opening in plastic sheeting. Combining a couple of ideas I had gotten from Halloween-L list members in early ’97 including Bob Andrews’ cemetery gate he had built in ’96 (which started the whole cemetery fence craze), I hoped to create an entrance unlike any I had seen before. Largely inspired by the Andrews gate, here’s what came of the journey that ensued as re-written.

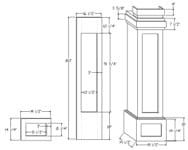

With most of my projects I find it helps enormously when I start with drafting up the project to scale fist. Here is a general idea of how I wanted my entrance to look, a bit gothic in design that would include gargoyles atop each pillar, smoke (fog) coming out of each one’s mouth, and a sign connecting the two sides. The important thing about the construction of this, to me, was that this not only be pleasing to the eye, but practical, in as much as moving and storing. And since the columns would largely be hollow, I decided to use them for storing the elements that would be part of the event, like the gargoyles and fog directing system. That meant the interior dimensions would be based on the Distortions’ foam filled latex gargoyle #DU1136 which stand 27″ tall and when turned a 1/4 turn will just fit inside a 15″ square interior space.

Then, considering the height of the arch included, I felt that 80″ high for the pillars would be adequate, which would give me almost that much head clearance under the arch and at the same time be low enough to store in a typical garage with an 8′ ceiling. In this blueprint you can see the doors that are built into the back of each column that will give me access to the storage area as well as for the fog routing system.

The original system I used to get the fog up to the gargoyles was a method that I called the Ice Vac, but since it moved fog using a fan, the fog was very thin and more of a mist than fog. Here we will be using the Vortex Fog Delivery System™, as it is by far the most effective method I have found yet to move fog over any distance without losing it’s viscosity. We will be installing a specially made Vortex Mini (must be special special ordered from us to have the exhaust on the end as shown here, as well as the inlet set to the needed position and the lid sealed permanently shut). The Vortex Column Fog Delivery Mini is 24″ long and just under the 15″ square that the inside of the columns will have, so this is a perfect fit. The idea is to install the Mini in the base of the left column. There will be more on the detail of the ducting system later, but it is important to your construction if you deal with this element of the build now.

Once you (later) fit your column with 1″ ABS or PVC pipe for the ducting, you will want to make sure to mount the Mini vertically so the fog-in (inlet) port is the lowest point of the unit, (the inside of the unit is slanted toward the lid) so that during use all the unspent fog fluid will automatically drain out and not build up inside where we will not be able to get to it.

Now on to the construction of the columns. The photo here shows the basic box configuration of the project. I used 3/4″ waferboard due to the cheap price and light weight. I do not recommend the use of particle board for props since it falls apart ruthlessly when exposed to moisture. The overall dimensions I used were 16 1/2″ deep / wide x 80″ high. Here is the cut out list;

(4) 15″ x 15″ interior floors

(2) 16 1/2″ x 16 1/2″ tops

(4) 16 1/2″ x 80″ sides

(2) 15″ x 80″ fronts

(1) 15″ x 56 3/4″ door

(1) 15″ x 25″ door

(2) 9 5/8″ x 15″ top back

(1) 12 7/8″ x 15″ lower back

(1) 15″ x 44 5/8″ lower back

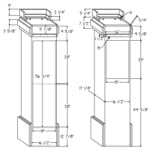

(expansion chamber cover)

Here you can see the backs of the columns as they will stand during use. Obviously the back dimensions differ, since one side (right unit as shown on the left of this rear view photo) will house the gargoyles and the other side will house the expansion chamber and fog ducting. The construction of the boxes here are simple; butt-joined yellow water resistant woodworker’s glue (Titebond II) and 1 1/2″ staples in each joint. You can substitute 2″ drywall screws for the staples if you are careful to predrill each hole. Notice in the photo above right (double click images for expanded view) that the sides of each box fully overlay the front and 3/4″ backs.

Also, each column has a floor mounted at the ground level inside the four walls, but the top is overlaid down onto them. This is so when our entry is exposed to rain, we will not have the end grain of our walls on the top where water could possibly stand for extended time, since the box itself is the armature to this build we will rely on for it holding up over time.

That is why the finished columns are 80″ high and the sides and front in the cut out are 79 1/4″. Before assembling your boxes, measure to the entry point on the right side of the column shown on the far right of the above photo and cut out a 2 1/2″ hole for the fog inlet pipe. Before closing up the bottom area of this column, mount your Vortex Column Fog Delivery Mini inside and suspend with a few 6″ shelf brackets below the Vortex at the right level for the duct to exit the hole. Here is a look again at the back view of this complete system.

A quick breakdown of its elements are;

(A) 1″ PVC quick disconnect

(B) 1″ PVC valve

(C) 1″ PVC pipe

(D) Vortex Column Fog Delivery Mini

(E) 2″ ABS clean out 90 degree elbow

Next we will need to put the decorative trim on the boxes as shown here. Each piece will be fully overlaid to the box. You can make these using the same 3/4″ waferboard material as the box. Notice the front of each column is recessed 3/4″, giving depth to the structure. This is obviously an extra step that can easily be skipped if you wish, but this how-to will detail creating this feature. You will have a choice of cutting out the openings out of sheets of the wafer board with a jig saw or another slick way of achieving clean, straight lines on these inside edges is to assemble these as face frames. You cut out each section and assemble them together using a pocket bore jig, machine, or you can make a wooden jig yourself if you will only be using it a few times.

The one shown is a Pock’it Jig Kit you can order from a tool supply like Woodcraft . You will need this drill bit as well, so your center hole and counter sink are correct. Also the long square drive screw driver bit is needed if you are using the square drive pocket bore screws as shown. Then on the back side of each rail (horizontal piece of any face frame) so you can hold the joint flat against a table, place glue between the joint and then drill a small headed face frame screw through it and into the stile (vertical piece of any face frame). Stiles are always top to bottom of the outside parameter of a frame, while rails are always the distance between the stiles as denoted by the dotted lines in the blue print above. Here are the cut outs for the two face frames only;

(2) 16 1/2″ x 80″ front -or-

(4) 3″ x 80″ stiles

(2) 10 1/4″ x 10 1/2″ rail

(2) 18″ x 10 1/2″ rail

(2) 14 1/4″ x 19 1/2″ front -or-

(4) 3″ x 14 1/4″ stile

(4) 3″ x 13 1/2″ rail

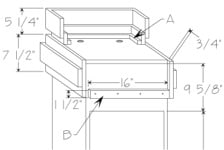

Here is a look at the columns with all the trimmings from a rear view. You will notice on the top of each are 5 1/4″ tall assemblies that have been added to each original box with glue blocks (A), which are 3/4″ x 3/4″ pieces of wood that we can screw through and into the bottom of the assembly and then through and into the top of the column.

Remember to use glue on these joints and either screw or staple on. These are the light shields needed to keep the light I will have illuminating the gargoyles from shining back down in the eyes of the TOTs. Here is a closer look at the exact dimensions of each. Some important items to notice are the outside trim pieces extend back 3/4″ behind the column box, and there is a 1 1/2″ x 16″ piece of wood attached 5 7/8″ below the rear edge of the top (B). This is a seat for your sign to fit into, which is obviously detachable.

Looking at the aerial view down on the top of the two columns as well as down on the light shield, you can see clearly which pieces overlay, or “butt” to which mating piece. Not shown here is the hole you will need up through the center of each top for the fog duct which must be measured precisely for once you have fitted your gargoyles with the appropriate hose as will be covered later in this how-to. You will however see the two 1 1/2″ holes needed in each top for your gargoyle display lights. You can then simply mount some ceiling lamp bases as shown here which can be found at any hardware store, underneath the top. Just mount with screws up through the base of the socket flanges and into the underneath side of the top.

Here is a run down of each of your trim pieces along with a cut out list for all the trim pieces only of our build;

(4)7 1/2″ x 17 1/4″ (A)

(4) 7 1/2 x 18″ (B)

(4) 3 5/8″ x 18″ (C)

(4) 3 5/8″ x 18 3/4″ (D)

(2) 16 1/2″ X 80″ (FRONT E)

(2) 7 1/2″ x 18″ (F)

(2) 3 5/8″ x 19 1/2″ (G)

(4) 15″ x 17 1/4″ (BASE A)

(2) 15″ X 18″ (BASE F)

(4) 14 1/4″ X 18″ (BASE C)

(2) 14 1/4″ X 19 1/2″ (BASE FRONT G)

(4) 2 1/4″ X 3 1/4″ (H & L)

(4) 4″ X 4″ (I & M)

(2) 2 1/4″ X 16 1/2″ (J)

(2) 4″ X 18″ (K)

Apply each piece of trim with plenty of glue and permanently attach. Next we will hang the doors inside the openings of the backs using continuous piano hinges, 3/4″ x 3/4″. You can add a magnetic lock to each door to keep it closed or use cam locks like I did so there was no chance that a TOT was able to go around to the back and open the doors during use.

Now we will move on to the sign. For this I chose to use 3/4″ flake board again, as it is so easy to work with and light weight. In this blueprint you will see that I have laid out a grid on 6″ wide by 2″ high stop sets, beginning with 3″ off the bottom up to 23″ high, cut out of a 96″ sheet. If you measure out and mark each point where the lines meet and then connect the dots, you can easily smooth out the curve to a radius that looks perfect to the eye. I used a jig saw to cut mine out which is the easiest tool to use here. You can add a 1″ wide piece of trim to the top and bottom edges of this sign to give it a little more zing. Just attach it with 2″ drywall screws every 8″ and it will bend to the radius very easily.

Here is a shot of the rough build completed. One thing that will be obvious here is that I added angled footings underneath my columns to match the slope of the driveway in front of my garage. I made them removable as a separate part to the build and it is a good thing too, since I had to remove them 2 years later when I moved to a new place. If you want to add an additional bottom “platform” piece to yours as is shown below my angled additions, just cut two pieces of the flake board at 19 1/2″ x 21″ to give a 3/4″ footing to the sides and the front. You will also notice small light shields at the top of each of these columns, as I underestimated the size they would need to be to fully block the view of the bulbs which is just tacky. Something else that may be apparent and that is I rounded all the exposed edges to give it more of a crafted look and most importantly to make it durable. Square edges are just asking to get dinged up with use. Build time will vary based on your space and tools, but this took about 4 hours to get to this point, not including the installation of the expansion chamber.

Next I installed the plumbing, or ducting system for the fog. Once again, this is the old Ice Vac system I was working on many years ago that would draw the fog from the fog machine which was using a venturi system at the nozzle and then using a small vacuum cleaner slowed down to a very slow speed, would push the fog up through the duct work. This system worked, but just barely. The new system outlined at the start of our how to works about 5 times as effectively, with no moving parts or need for electrical power. I will post the photos of the new arrangement as soon as I get the opportunity. For now we will use this photo to show how I have broken the incoming fog into two lines and have adjustable valves on each, since without it, the first gargoyle closest to the fog machine would get almost no fog at all.

At the top of the right duct, just above the valve you can just make out the quick connector that is used to clamp on tightly to the flexible fog hose coming out of the bottom of the gargoyle and through the top of the column. This makes it a snap to take the gargoyles down for storage each year. In the blueprint here you can see the that the 1″ PVC fog duct travels out the back of this column, through a hole in the sign and then across the back of the sign to get to the other column. You will need these same quick connectors on each end of the sign to make it’s removal and replacement possible. Of course the pipe lengths connected with 45 degree angles are permanently attached to the back of the sign itself, which is then attached to each column with about six 1 1/2″ drywall screws each end.

We will move on now to the painting stage. For mine I chose to do a faux marble type of look and painted the entire assembly with black paint (acrylic or latex to really seal off of the elements well in case of rain). Next I used a sea sponge to apply shadowy outlines of the veins with a thinned-down light green color. At the paint department of the local Home Depot or the like you will find a thinning agent or glaze such as the FolkArt Wash Medium that will give your paint almost a translucent appearance without making it too watery to work with. After the cloudy shadows were applied the veins were applied with a very small, round tip brush using the lighter colored green that I had used for the clouding, but with a lot less of the glazing for thinning, as I want the veins to be pronounced against the background. You will still want to thin it down some so it isn’t just stark. Apply the veins with the brush pushing against the bristles instead of with normal painting strokes. This causes the paint to flair out in sharp pointed areas as you go, looking more like veins going off of veins. Then immediately go over the veins while still wet with a large goose feather and flick at the paint from side to side. This causes even more veining to occur.

Since my columns would be viewed in the darkness I exaggerated the marbling veins so they would be more visible than more realistic type veining you might do on a pillar inside a home. After the feathering is done, (do only one small section at a time to keep the paint wet and workable) allow to dry overnight. Then go over the entire thing with about 4 coats of clear paint to protect your investment from rain and weather. Be sure to get clear paint that is recommended for going over the top of paint and not stain or raw wood! This is a special clear that costs much more than normal clear (of course) but does a nice job with a lot of build for a thick, protective finish. I used Man “o War high gloss clear spar varnish coating.

Next I attached some wooden letters from the hardware store painted with gold paint and (very important) clear coated. The gold paint goes bad if you look sideways at it without this extra clear coat to protect it and I didn’t want to re-do my letters later. Each letter is screwed on from the back without any glue after the entire sign had been painted and marbled so if I ever desired to change the name it would be no problem. Next I installed some carriage lights to the front of the column to light up the entrance for the TOTs in which I installed “black” party lights so it would be dim lighting. To get 110 electricity to the far column from where the fog and the electrical comes in to the left one, I routed an extension cord to outlets at the top of each column that is fitted with female connectors to both ends and zip tied to the fog duct on the back of the sign.

The gargoyles were drilled up through from the center so a fog duct could exit the mouth. The best way to cut out a path in the foam filling is with an electric carving knife (yes, just like the one you use on the turkey). I then fitted sections of plastic (1 1/4″ diameter nipple) vacuum hose that can be purchased by what ever length you want at the hardware store normally used for swimming pool vacuums. As mentioned earlier, this ran up from the column below and fitted at the mouth, permanently installed in the monster but the pig tail section from below clamps instantly into the PVC quick fitting. This clamp action helps hold each gargoyle in place, along with them pinching against the sides of the light bulb shield.

This picture shows the fog as it looks using the old Ice Vac system which is nothing more than a mist compared to the thick, dense fog they emit now with the Vortex System™ in place. The lights I use behind the shield are two different colors. One red and one green both set up on blinkers so while in operation the color that is illuminating each gargoyle changes from red to a combination of red and green or to just green / back and forth. And the colors are completely stand-alone, so the two monsters never look exactly the same as each other at the same time. That means that the fog is never the same color either, which is sort of a cool effect. Not very visible in the photo here are reading lamps I painted to match the marble and mounted on the sides of each column near the top, pointing back at the sign so that it is visible to read at night. I run green light bulbs in each with the one on the right hooked up to a Fright Light from Haunt Master Products, so it looks like the electricity is going in and out sporadically on just the one. One final thing I might mention is if you attach two 2″ unidirectional wheels to the bottom back of each column, it will allow you to tip each one back and wheel it around by one person just like using a dolly. It makes it pretty simple for set up and take down.

Have fun with your project! See a short video clip of the Entrance with old fog system.